Are you looking to reduce costs and improve quality? Use the Six Sigma business framework!

- What is the Six Sigma framework?

- What are the two Six Sigma methodologies? DMAIC and DMADV explained

- How do you calculate Sigma?

- What are the primary objectives of the Six Sigma framework?

What is the Six Sigma framework?

Six Sigma is a business framework that provides an organization with two methodologies to reduce costs and improve quality thus enhancing the profitability of the business.

These two methodologies are DMAIC and DMADV.

What does the term Six Sigma mean?

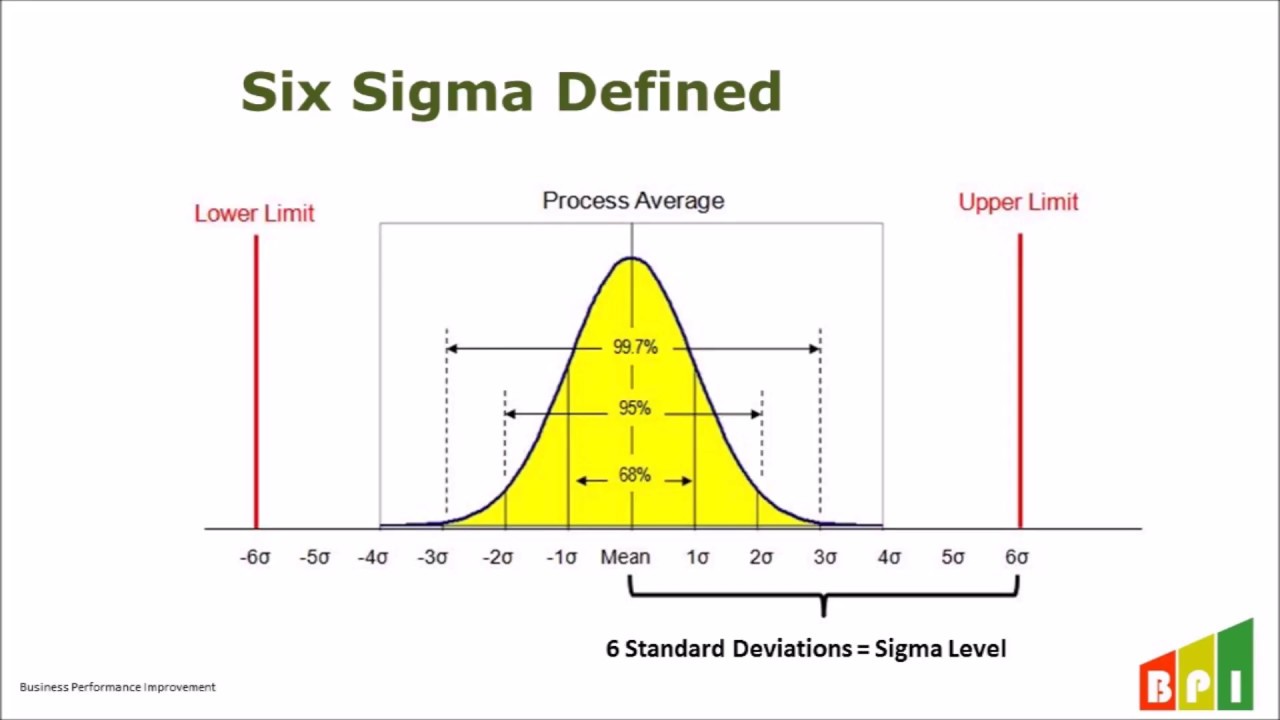

The term Six Sigma means six standard deviations from the average.

A Six Sigma level of performance has 3.4 defects per million opportunities (3.4 DPMO).

How do you calculate Six Sigma?

Here’s how to calculate the Six Sigma level of quality:

Who created the Six Sigma framework?

If you want to improve something, involve the people who are doing the job.

Bill Smith, the “father of Six Sigma”

The Six Sigma business framework was developed in 1986 by quality assurance engineer Bill Smith during his employment at Motorola.

At the time, Motorola top management was frustrated with the quality of the brand’s products.

Bill Smith convinced Bob Galvin, the CEO of Motorola at that time, that improvement of their products was possible and he proposed Six Sigma.

With Six Sigma, Bill’s goal was to improve manufacturing quality by identifying and removing the causes of defects and minimizing variability in manufacturing and business processes.

Six Sigma was a huge success by reducing the defects to 1/100th in four years.

Two years after the new strategy was implemented, Motorola won the prestigious Malcolm Baldrige National Quality Award.

Between 1987 and 1997, Motorola reported the following results:

- 5x growth in sales

- 20% increase in profits per year

- $14 million saved

- the stock price compounding to an annual rate of 21.3%

In 2005, Motorola attributed over $17 billion in savings to Six Sigma. Other global companies began implementing the Six Sigma method throughout the 1990s such as Honeywell and General Electric which led to the widespread adoption of this novel and effective business strategy.

What are the two Six Sigma methodologies? DMAIC and DMADV explained

DMAIC methodology is used to improve an existing business process.

DMADV methodology is used to create new processes in order to achieve customer needs.

Both DMAIC and DMADV help the organization to achieve the following essential goals:

- Reduce the number of defects to less than 3.4 per million opportunities;

- Find quality-related solutions to problems using data and statistical tools;

- Meet financial and business objectives.

DMAIC is the acronym for:

D – Define the objective of the project, create the team who will complete the task, select the process the team will be improving, identify and measure the impact the problem has on the customer.

M – Measure the performance of the process by creating and executing a data collection plan that provides reliable and significant data. Identify the variance that needs to be eliminated in order to improve the business process.

A – Analyze the collected data and identify possible causes of the problem. In this phase, the team is able to quantify the financial benefit of solving the problem.

I – Improve. Now that the problem has been identified, it is incumbent upon the team to find a solution to improve and optimize the business process. The team then tests this proposed solution to see if it is effective and financially viable.

C – Control. In this phase, the team documents the new solution that they have created so that it can be passed on to process owners. The project team then implements the solution according to the timeline and key milestones they have developed. Once the solution has been implemented, the project team monitors it for several months and if it meets performance expectations turns it over to the process owner.

DMADV is the acronym for:

D – Define design goals that are consistent with customer demands and the enterprise strategy.

M – Measure and identify CTQs (characteristics that are Critical To Quality), measure product capabilities, production process capability, and measure risks.

A – Analyze to develop and design alternatives

D – Design a business model that helps meet the customer’s needs

V – Verify that the new business model helps meet the customer’s needs, set up pilot runs, implement the production process and hand it over to the process owners.

What are the primary objectives of the Six Sigma framework?

The primary objectives of the Six Sigma framework are the following:

- Identify and reduce errors

- Increase the efficiency of business processes

- Achieve customer satisfaction

- Design new processes

- Improve the performance of a product

Sources: sixsigmadaily, shmula

Join the Conversation

We’d love to hear what you have to say.

Get in touch with us on our LinkedIn Page, Facebook Page, Twitter or TikTok.